Power Management

Test sockets for power management ICs (PMICs) play a crucial role in ensuring reliable electrical contact during testing while accommodating the thermal and power-handling requirements of these ICs.

Important Specifications

- Current and Voltage Rating

- PMICs often handle high current (>10A), so sockets must have low resistance contacts to minimize power loss and heating.

- Voltage ratings should match or exceed the IC’s operating voltage.

- Contact Resistance

- Low resistance (<50 mΩ) ensures minimal voltage drop and power loss.

- Consistency over repeated insertions is critical.

- Thermal Performance

- The socket material and design should support heat dissipation to prevent thermal damage.

- Some high-power applications require sockets with integrated cooling solutions.

- Pin Count and Pitch

- Must match the IC’s footprint (e.g., BGA, QFN, LGA, or custom packages).

- Fine-pitch designs (<0.5mm) require precision engineering to avoid signal integrity issues.

- Signal Integrity

- For high-frequency PMICs, the socket should have minimal parasitic inductance and capacitance.

- RF shielding may be necessary for noise-sensitive applications.

- Durability and Insertion Cycles

- Should withstand thousands to millions of cycles, depending on usage (engineering validation vs. mass production test).

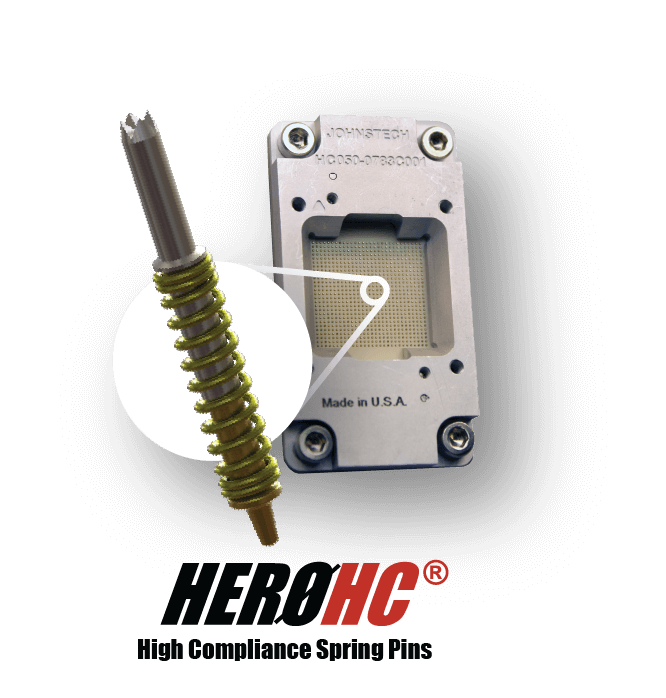

- Material and Contact Technology

- Spring pins (pogo pins), elastomeric connectors, or micro-coaxial structures can be used.

- Materials like beryllium copper or gold-plated contacts improve conductivity and longevity.

reliable electrical contact during testing