System-Level Test (SLT)

What is System-Level Test (SLT)?

System-Level Test (SLT) is a testing methodology used in semiconductor manufacturing to validate the performance and reliability of integrated circuits (ICs) in real-world application conditions. Unlike traditional functional tests, SLT evaluates chips within a system-like environment, running actual software or firmware to detect defects that may not be captured by earlier test stages. A crucial role in System-Level Test

Role of Semiconductor Test Sockets in SLT

A semiconductor test socket plays a crucial role in System-Level Test by providing a reliable electrical and mechanical interface between the device under test (DUT) and the test system. These sockets allow for:

- Repeatable, High-Performance Connections: Ensuring consistent electrical contact without damaging the semiconductor package.

- Thermal and Power Management: Some test sockets incorporate features like heat dissipation mechanisms or controlled power delivery to mimic real-world operating conditions.

- Durability for High-Volume Testing: SLT requires repeated insertions and removals of devices, making robust test sockets essential for maintaining reliability over extended test cycles.

- Compatibility with Various Packages: Test sockets are designed to accommodate different semiconductor package types, ensuring proper alignment and signal integrity during SLT.

Johnstech Products Help Make SLT a Success

Johnstech prides itself on product quality and reliability, and our contactors play a crucial role in System-Level Test. When doing SLT a consistent and true response is needed to make sure the end product will function when deployed in the field.

All Johnstech products go through extensive characterization and qualification processes prior to release and in production are subject to strict inspections to make sure anything being sold meets our standards.

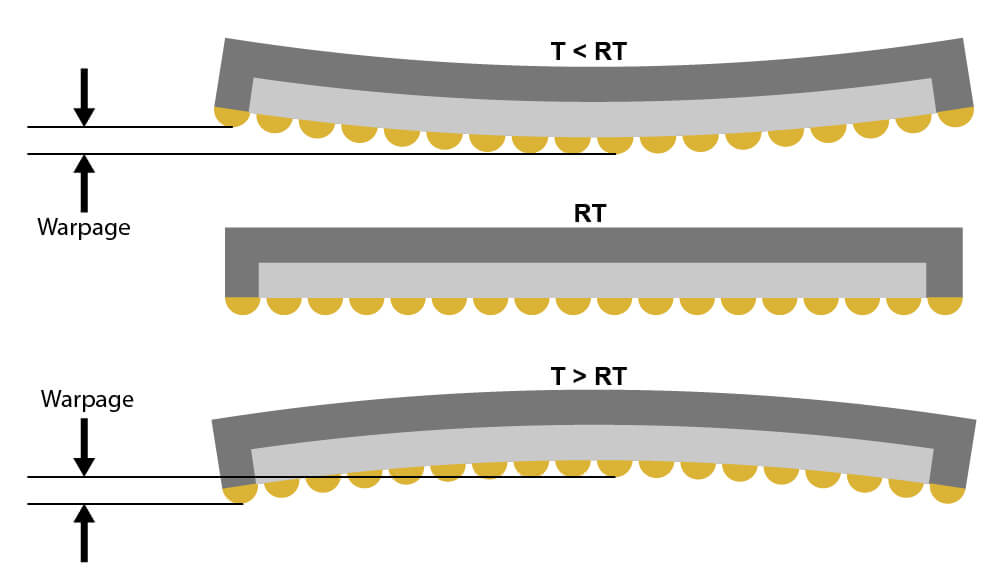

Many of the semiconductors being tested have very large arrays with 1000’s of IO, the HERØHC® spring probe line is ideally suited to this challenging application, it has 0.750mm compliance that can help ensure your testing is consistent and repeatable without the worries that your set up could have planarity issues or the DUT might have warpage issues.

- HERØHC® Spring Probe Contactors provide industry leading compliance relative to the free length of the pin

- HERØHC® is designed with a compliance range to overcome warpage challenges > up to 0.75mm of travel to final test height of 2.5mm

A high compliance probe can help decrease any issues that might be encountered in a test environment.

- Handler stack ups can vary and could pose an issue to test, using a high compliance probe allows for a wider range in the stack up variance that can still be handled.

- Multi-site test set ups can be susceptible to varying test heights across sites.

Sometimes SLT is across temperature ranges, our Spring Probes are rated for performance from -65°C to 175°C, so everything is covered.

If you have an SLT application please contact Johnstech International, we can work together to provide you with a product that will meet and exceed your expectations.

Click Here for more information about HERØHC®.